last update 1/18/2000

Fringe Correlation Method

The Fringe Correlation Method (FCM) is designed for high accuracy geometrical

measurement of deflection or deformation of smooth objects or surfaces. A very important

advantage of the method is the fact that the surfaces or objects may move during the image

acquisition. Only one single image has to be acquired for analysis of the surface deflection.

Therefore, using high speed cameras, a high speed motion analysis of the surface deflection

is possible.

The basic idea of this method is to use the in-plane displacement of projected fringe patterns

to determine out-of-plane surface deflections. Setup and usage of the FCM is very simple: A

regular slide projector with a simple black/white fringe slide projects a fringe pattern on the

surface at a distinct angle relative to the surface normal vector (figures 1 and 2). Any local

out-of-plane deformation or deflection of the surface results in a local displacement of the

fringe pattern. A camera, set up at a different angle relative to the surface normal vector,

acquires images of the fringes in a reference position and in the deflected position. The

fringe displacement can be detected and determined at subpixel accuracy by using

correlation techniques in frequency domain. A transformation factor, the FCM-factor, is used

to transform displacements into deflection values. The resolution of the method can be

influenced by changing the angles between projector and surface normal vector and between

projector and camera (see figure 2).

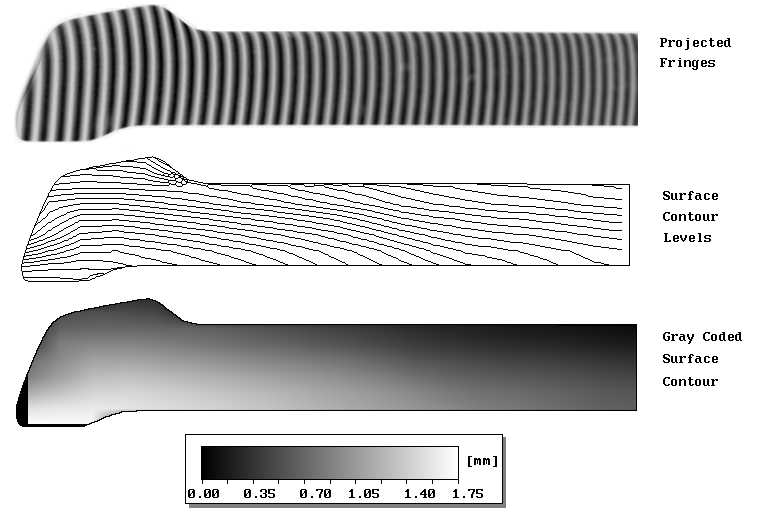

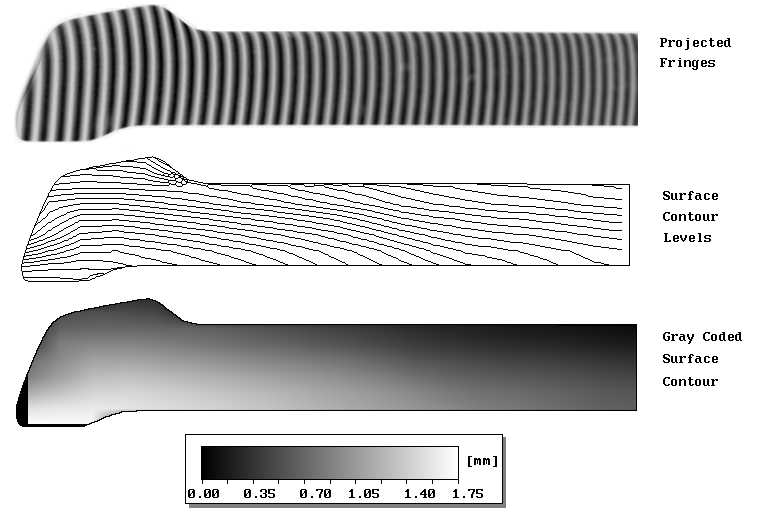

Fig.1: Typical Surface Deflection Measurement: Helicopter Rotor Blade with Special Tip Shape;

Projected Fringes and Measured Surface Contour after FCM Analysis

Fig.2: Setup of projector and camera for deflection measurement

Back to FIBUS Home Page

Back to Image Processing

Copyright © 2000 The

FIBUS Research Institute, Dr. Reinert H. G. Mueller;